Radiant Heat + Wood Flooring

A common question: “Can wood flooring be installed over radiant heat?” Yes. Yes, it can.

Just make sure you use compatible products. Take the minutes you need to read the instructions from the heating system and wood flooring manufacturers to make sure they will play well together.

This blog post covers:

+ Types of radiant heat

+ How radiant heat works with wood flooring

+ What to know about installing wood flooring over radiant heat

+ Tips based on type of flooring (e.g. engineered vs. solid, floating vs. nail- or glue-down)

Types of Radiant Heating

There are two types of radiant heating systems: electric or hot water (hydronic).

Electric radiant heat uses loops of resistance wire cable and mesh mats to transfer heat under floors. These systems, often installed in a single room such as a bathroom, are controlled with dual sensing thermostats that combine input from a floor sensor with a room thermostat. When the heat dips below or rises above a predetermined temperature, the heat flow is cycled on and off. A few of these systems can control voltage in relation to room temperature, and some systems include self-regulating elements to further control heat output.

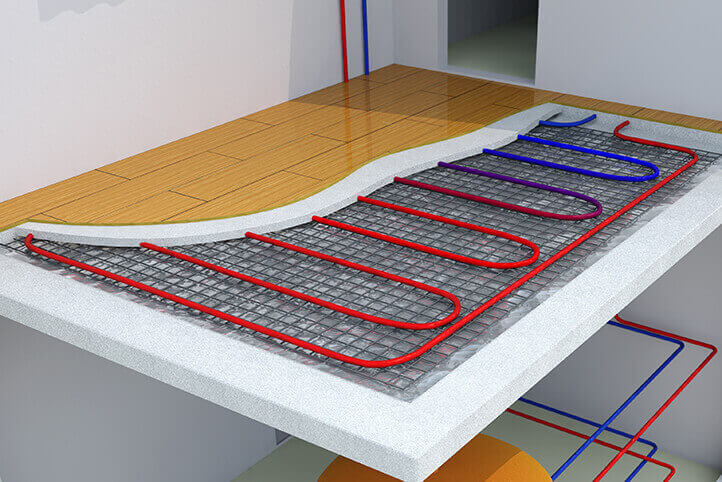

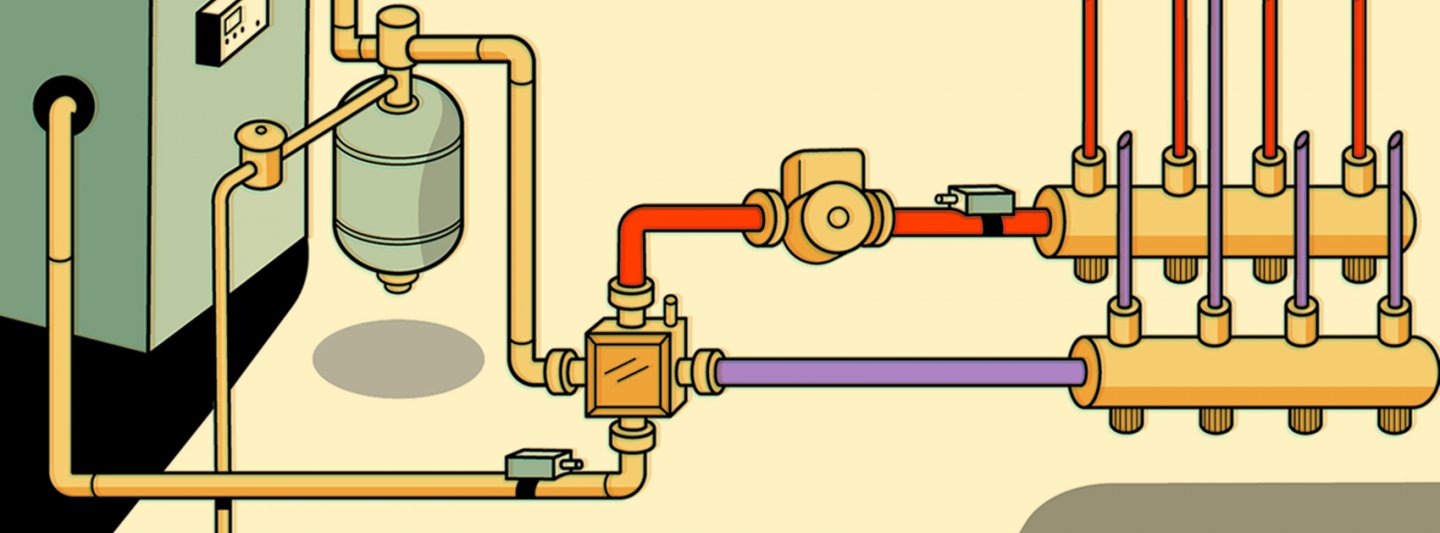

Hydronic radiant heating systems, which are the most popular and cost-effective way to heat an entire house, work by pumping hot water from a boiler or water heater through loops of polyethylene tubing under the installed flooring. With this system, you can control the water temperature, as well as the volume of water, and the duration of the water flow per pulse.

How Radiant Heating Works

With radiant heat, the heat source is installed directly beneath the flooring. Because having the heating source directly beneath the wood dries out the flooring more than traditional heating systems do, it is good to keep two things in mind:

+ Types of wood flooring that are best suited for radiant heat subfloor are products that have a higher level of dimensional stability.

+ A humidification system is all the more important for minimizing gaps between boards that come from shrinkage due to an overly dry home environment

Maximizing Wood Flooring Stability Over Radiant Heat

Engineered vs. Solid: Engineered wood flooring generally is more dimensionally stable than solid wood flooring. That means it reacts less to increases and decreases in moisture than solid wood flooring does. But that’s a generalization and engineered flooring does have its own reactions when humidity levels stray too far. (Learn more: “Humidity Matters”)

Species Matters: Certain species are known for their inherent stability such as North American oak, American cherry, and American walnut. Denser species such as maple and Brazilian cherry are less stable.

Saw Cut Makes a Difference: Quarter-sawn and rift-sawn wood flooring is more stable in width than plain-sawn wood flooring.

Strip vs. Plank: Narrow boards are more stable than wide boards. Strip wood flooring comes in a 3” or narrower width. Plank flooring is cut at 3 ¼” or wider.

What to Know About Installing Hardwood Floors Over Radiant Heat

Unlike traditional heating systems that switch on as needed, radiant systems work most effectively, and with less trauma to the wood floor, if the heating process is gradual, based on small, incremental increases in relation to the outside temperature.

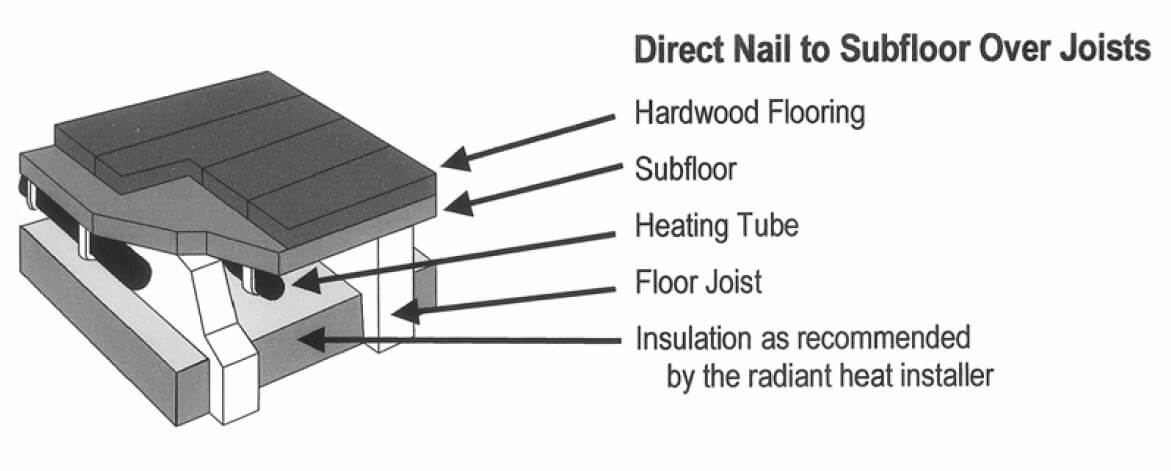

When installing wood flooring over a radiant-heated system using a nail-down method, avoid penetration of the heating element.

Radiant Heating + Subfloors

Radiant-heated subfloor systems can be concrete, wood, or a combination of both.

If the subfloor is concrete and it has cured, turn the heat on, regardless of season, and leave it on for at least five to six days to drive out residual moisture before installation of the wood flooring.

Some installation methods, particularly glue-down applications, require the heat to be reduced or turned off before installation, so the adhesive does not cure excessively.

With water-heated radiant-heat systems, a pressure test must be performed and documented by a qualified plumber, or the system installer, prior to beginning the installation of the wood flooring.

Wood Floor Installation Methods with Radiant Heating

The following installation and subfloor systems can be used successfully over radiant heat:

+ Glue-down (engineered or solid)

+ Floating engineered

+ Direct-nail to wood subfloor (engineered or solid)

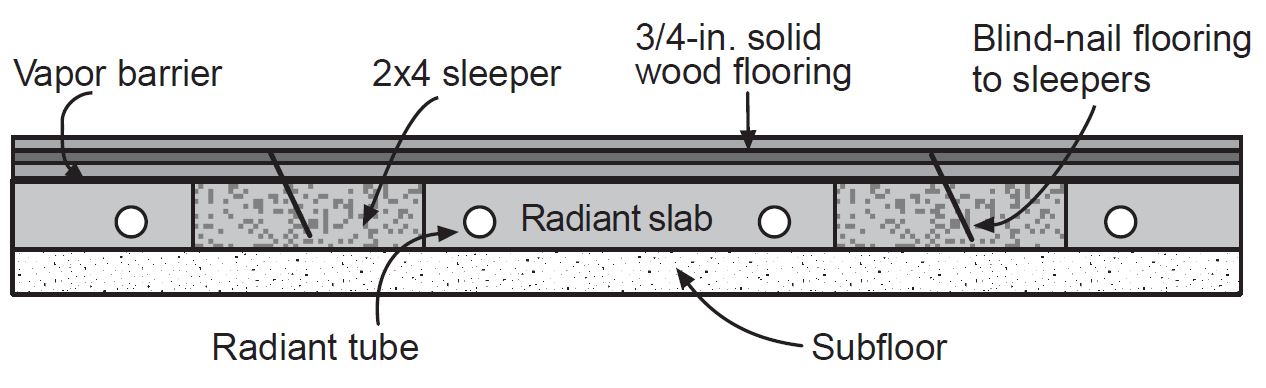

+ Direct-nail solid tongue-and-groove wood floor to sleepers

+ Single layer of plywood on sleepers

+ Double plywood floating subfloor

Tips for Wood Floor Installation, by Method

When using the glue-down method of installing wood flooring, follow the adhesive manufacturer’s instructions:

+ Use an adhesive approved by the radiant heating system manufacturer

+ The heating system might need to be turned off before installation; follow the adhesive manufacturer’s instructions

+ The maximum allowable subfloor surface temperature should be 85°F (29.44°C), unless noted otherwise by manufacturer instructions (adhesive or radiant

heating system)

+ Expect some shrinkage during heating season

When installing wood flooring by nailing down to a wood subfloor method:

+ Always check for subfloor moisture

+ Solid wood must be properly acclimated to normal living conditions

+ Be sure fasteners are not long enough to penetrate the heating elements

+ The maximum allowable subfloor surface temperature should be 85°F (29.44°C), unless noted otherwise by manufacturer instructions (adhesive or radiant heating system)

When installing solid tongue-and-groove wood flooring by nail-down over sleepers:

+ Using solid wood flooring 4 inches and wider is not recommended

+ Solid wood must be properly acclimated

+ Do not use short boards

+ The maximum allowable subfloor surface temperature should be 85°F (29.44°C), unless noted otherwise by manufacturer instructions (adhesive or radiant heating system)

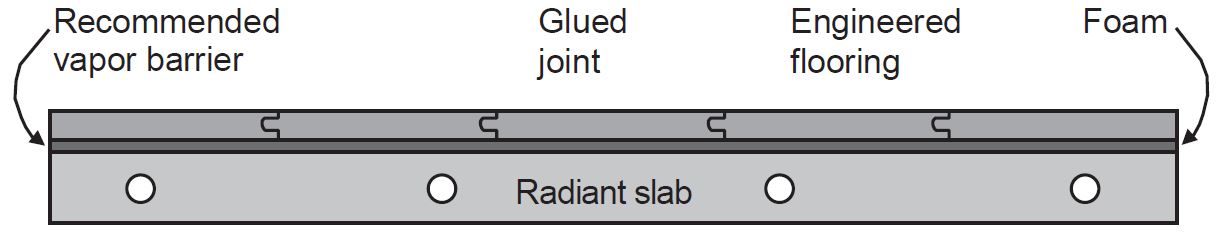

When floating engineered wood flooring:

+ A 6 mil or better polyethylene vapor retarder should be installed over concrete subfloors.

+ A foam or resilient underlayment recommended by the flooring manufacturer must be installed prior to application of the wood flooring

+ Use an adhesive approved by the manufacturer for side and/or end joints

+ The maximum allowable subfloor surface temperature should be 85°F (29.44°C), unless noted otherwise by manufacturer instructions (adhesive or radiant heating system)

Learn more about radiant heat and wood flooring by contacting your Palo Duro sales manager, or call our inside sales team at 303-375-0280.

Learn more about other wood and luxury vinyl flooring topics and products by:

+ Reading on the Palo Duro blog

+ Subscribing to the Palo Duro newsletter

+ Joining us on social media (Instagram,

Facebook, Twitter and Houzz)

Related Blog Posts

Water + Wood: Understanding the Basics

(Additional sources: National Wood Flooring Association and World Floor Covering Association)