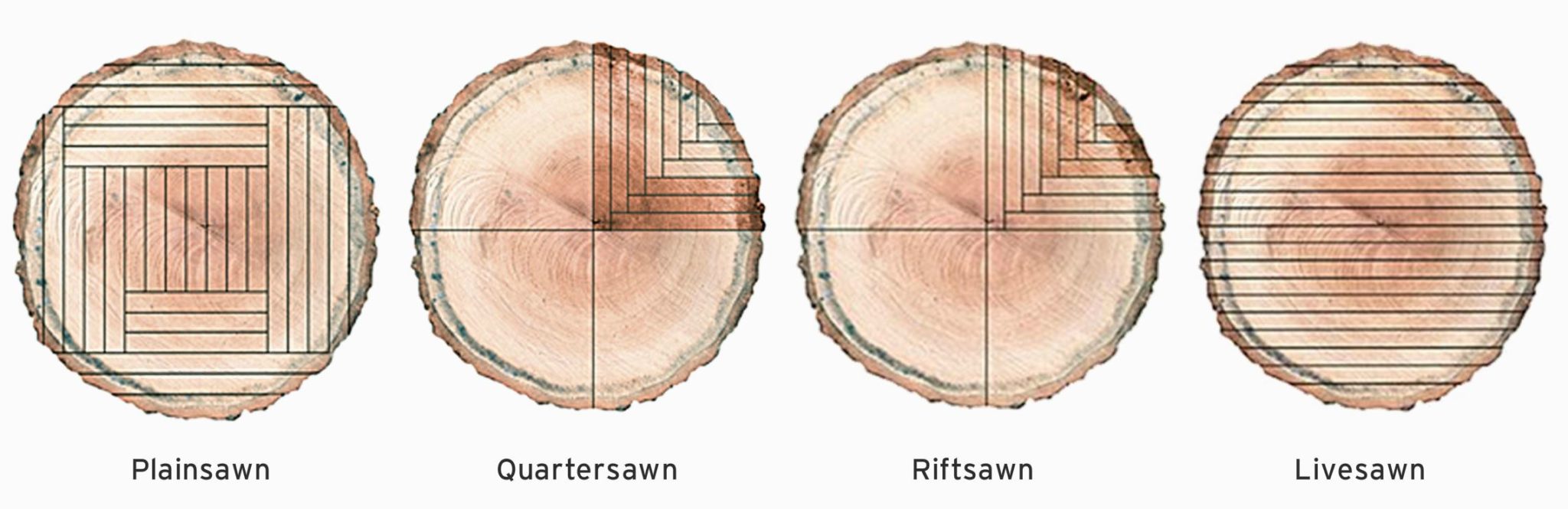

We talked recently about wood cuts: quarter, rift, plain and live. We also talked about the forest-to-floor process. We even got in the dirt of the forest with a recent tree anatomy guide and how that anatomy relates to wood flooring.

Now we’re connecting how those factors, especially how the wood is cut and acclimated, affect wood floor performance.

Wood Cuts + Reactions to Moisture

The type of cut influences how wood reacts to increases and decreases in moisture. Wood is hygroscopic, meaning it takes in and lets out moisture; it does this even after the tree is cut, milled into flooring, and installed in a home.

How wood is cut affects how the grain of that wood is exposed. That graining is key to the character and overall look of the flooring, but also to how moisture comes and goes with changes in the floor’s environment.

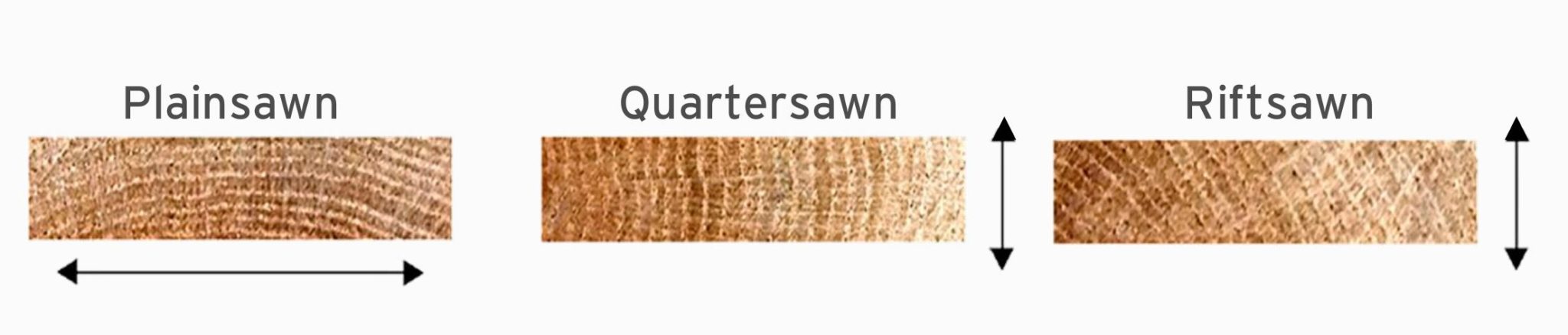

The direction of that graining – running lengthwise with the board, across it or at angles – is how the water in the wood moves. The graining is the system of pathways for water when it’s drying at a mill, acclimating in a home before installation, and taking in or letting off moisture due to the high or low humidity in a home’s environment after installation.

You can learn more about wood cuts, what makes a board quarter-sawn, rift-sawn, plain-sawn or live-sawn, in “Four Types of Wood Cuts.”

Here’s the gist of how different cuts react to moisture when installed as a floor:

- The quarter-sawn cut of a tree produces more dimensionally stable wood, meaning it reacts less when humidity changes in the home where quarter-sawn flooring is installed. Quarter-sawn boards shrink and swell in the board’s thickness, more than across its width.

- Plain-sawn, or flat-sawn, boards tend to shrink and swell widthwise with release and absorption of moisture.

- Live-sawn wood reacts to moisture changes with shrinking or swelling in all directions.

The water and wood relationship is a significant part of manufacturing, installing and maintaining a wood floor. Managing that water within the wood begins at the lumber mill.

How Wood Cut Affects the Drying Process

The drying time wood needs depends on wood species and the way the wood was cut, which affects the exposure of its medullary rays, or the grain and flecks we see as character in a floor.

For example, plain-sawn boards do not need as much drying time as quarter-sawn boards. The medullary rays of plain-sawn boards are perpendicular to the surface.

Not all saw mills are equipped to handle rift- and quarter-sawn lumber, which need to be dried separately to ensure consistent, proper results. If they are dried together, drying will not happen equally throughout the boards. The distinct wood cuts require different amounts of drying time.

Excessive moisture content in wood during the manufacturing, storage and delivery process leads to challenges when acclimating wood flooring for installation. A floor with too much moisture for the environment where it was installed will shrink as it releases that moisture as vapor.

On the flip side, if wood is too dry for an environment, there can be problems caused by expansion of the boards. For example, if wood dried in an arid region like Colorado is shipped to a humid region like Florida, the floor will take on moisture in its new home. That’s OK. Knowledge of proper acclimation

will prevent problems.

The Bottom Line

Some basic knowledge of the interaction of wood cuts, acclimation and flooring behavior, especially by the professionals involved in a wood flooring project, will ensure success.

Wood flooring can perform well, regardless of its type of wood cut. It can perform well regardless of its need to adapt to a drier or wetter environment.

Success lies in being informed and in working with trusted wood flooring experts.